04/04/2016

BIT-IEM half day seminar on seismic isolation in Sabah, Malaysia

Structural cost reduction in seismic mitigation and retrofitting using base isolation

BIT has successfully organized a half-day seminar in Kota Kinabalu, Sabah in collaboration with the Institute of Engineers (IEM Sabah branch). The seminar with the theme on ‘Structural cost reduction in seismic mitigation and retrofitting using base isolation’ has received participation from more than 60 senior structural engineers and head of technical division from both private consultants and government agencies.

Held in Promenade Hotel, the first lecture introduced basic concept of earthquake engineering to the audiences. The presentation unraveled the theory and rationale behind ductility design in EC8 to allow engineers to understand the consequences that they have to accept in the conventional seismic resistant design of structure. Building codes are actually standardized guidelines based on several research findings that have been agreed on by the technical committee. Nevertheless, engineers have to be aware of the limitation and areas that are not fully covered within the codes. The scientific committee has to continuously work on improving the existing building codes from time to time. Then, the fundamental of seismic isolation have been presented. Structural response and performance of fixed-base and base-isolated building have been discussed. Last but not least, cost comparison between the two design approaches has been presented and discussed.

The second presentation covered in detail retrofitting of existing structure in Europe, particularly in Italy where earthquake is prominent. Thanks to decades of experiences in seismic retrofitting using base isolation, the speaker focussed on actual retrofitting projects of base isolation in reinforced concrete buildings, masonry structures and cultural heritage as well as industrial facilities. Cost analysis was also included using real example of two identical buildings. Besides seismic isolation, the presentation was concluded by introducing other energy dissipation devices.

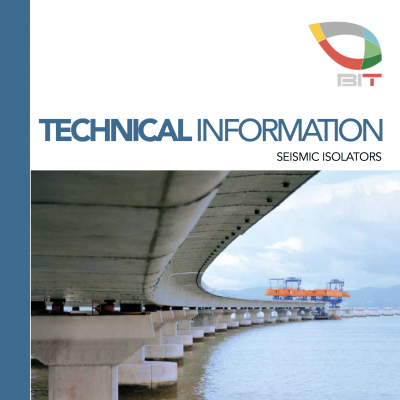

The last session focusseds on the technology and manufacturing capability of Malaysian manufacturer, Doshin Rubber Products (M) in high damping rubber bearing. Doshin Rubber is the manufacturing arm of Base Isolation Technology (Asia) and the company has successfully supplied and installed over 2000 high damping rubber bearings for the 2nd Penang Bridge. This is the longest bridge in Asia to be seismically isolated using high damping rubber bearing (HDRB). Among many other projects, the company is also supplying bridge bearings to local MRT tracks as well as seismic bearings for hospital and office tower in Indonesia.

TAG: | | |